Recently, we have often been questioning the differences between a thermal camera, specifically the GIS-320 thermal camera, and a laser methane detector or optical laser methane detector. Both can now be used together with drones to detect dangerous gas leaks. We will therefore compare their functions and applications.

The principle of operation of both devices is very different.

How does thermal camera for gas leak detection works?

If a thermal camera reads a scene without gas leak, objects in the angle of view will radiate and reflect infra-red radiation that will react through the lens and the filter on the detector. The filter only lets some wave lengths of radiation enter the detector from which the camera generates not compensated image of radiation intensity of the radiation (then we speak about the apparent temperature). If there is a cloud of gas between the lens and thermal camera, this gas will selectively absorb radiation to the extent of its spectral absorption and the amount of radiation passing through the gas which affects the detector will be lower. The principle is explained in detail in this article: Using thermal cameras to visualize gas leaks.

How does laser gas detector works?

Utilising laser technology, gas leaks are located by pointing the laser beam towards the suspected leak, or along the survey line. The laser beam directed at targets such as gas piping, the ground, etc., will reflect back a diffused beam from the target. The device will receive the reflected beam and will measure the absorptivity of the beam, which will then be calculated into methane column density (ppm-m).

But what about practice? We want a practical comparison

The practical comparison can be the same as the comparison of pyrometer and thermal camera. The pyrometer is a simpler instrument that allows hot-spots to be detected only at locations that we focus on the very narrow field of view of the “one point” detector that is used. The thermal camera, on the other hand, makes it possible to detect and measure hot-spots in the entire image which it is able to observe with its lens.

The GIS-320 thermal camera allows visualization and therefore detection of gas leaks on large areas due to the relatively large field of view (see the table below) and the large number of detectors. This is not only one (as with the laser methane detector), but with a resolution of 320×240, there are 76,800. Thanks to this, it is possible to scenario even very large areas.

During a one fly, you are able to control about 150m x 150m (on altitude 80 m) area or about line with length up to 1000 m.

Place for a conclusion

The conclusion is simple: the probability of finding a dangerous gas leak is much more likely and faster with a thermal camera, especially if you have to explore large areas such as technology and pipelines in modern manufacturing plants.

The GIS 320 thermal camera also allows you to detect many other gases: Benzene, Ethanol, Ethylbenzene, Heptane, Hexane, Isoprene, Methanol, MEK, MIBK, Octane, 1-Pentane, Pentane, Toluene, Xylene, Butane, Ethane, Methane, Propane, Ethylene.

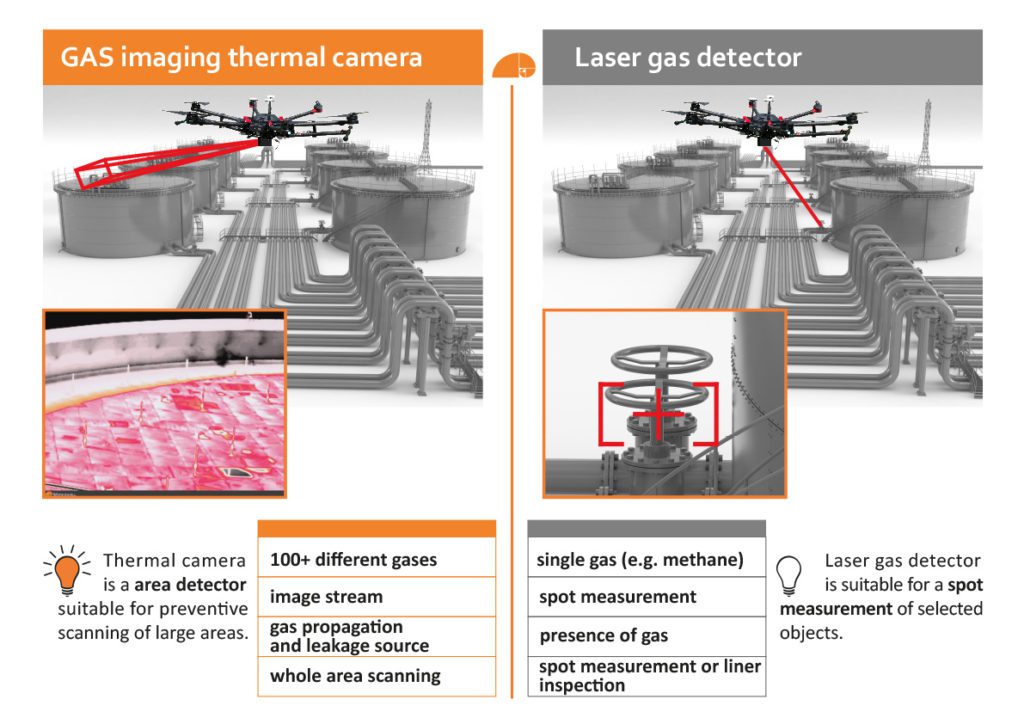

- We can say, that thermal camera is a „area detector“, suitable for preventive scanning of even large areas.

- Laser gas detector is suitable for spot measurement of selected objects (for instance valve, part of pipelines, etc.), or for line measurement.

Type of mesurement: image stream (try FOV calcualtor) spot measurement

Workswell GIS 320 for drones – optical gas detection with thermal camera

TESTING NEW DJI U10 GAS DETECTION DRONE SENSOR