OVERVIEW

Powerfull solutions for your problems

Thermal imaging camera uses: from power engeneering and power plants to agriculture and security sevices

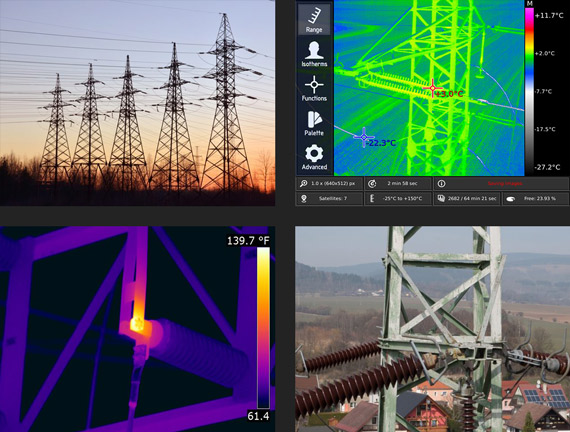

It’s almost impossible to imagine life without electricity. Yet even though almost every aspect of the modern world depends upon it, it’s all-too-easy to forget how demanding it is to produce and supply electric power for daily consumption.

After all, transmission and distribution networks are highly complex systems of interconnected energy sources, and they don’t run on their own. When failures occur within electricity networks, they can lead to blackouts, or worse – destructive fires.

Advanced thermodiagnostic tools have an important role to play in the prevention of these disasters. One such tool combines cutting-edge thermal imaging systems with the UAV, or drone, to give advance warning of a potential problem.

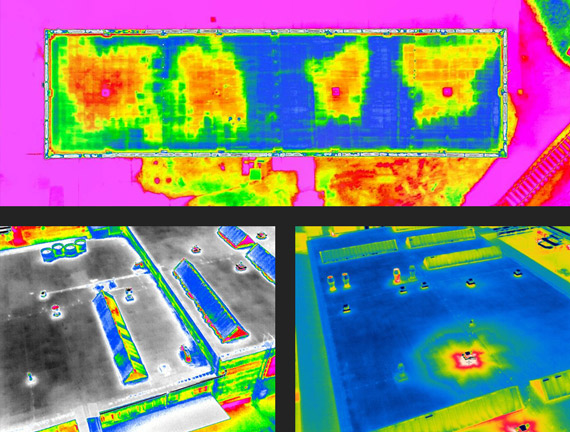

A thermal imaging camera uses infrared technology to detect and measure the amount of heat emitted by objects and surfaces. There is a fast and simple way to resolve the problem posed by the need for detailed flat roof inspections. This solution is a thermal imaging system, or thermal camera. Due to the heat difference between a dry roof, and a roof that has been penetrated by moisture, a thermal camera can fully diagnose an emerging defect. Depending on the roof’s construction, it can even be possible to localize and define the scope of the defect by seeing how large of an area is affected by moisture.

The physics behind the thermal image inspection of moisture defects is based on the fact that the dry part of the roof cools and heats more slowly than the wet part. Thermal image inspection using a thermal camera during or after sunset, when the roof has just been thoroughly heated, aids in the identification of moist areas because the dry parts of the roof cool slower than the wet places, which have a higher thermal capacity.

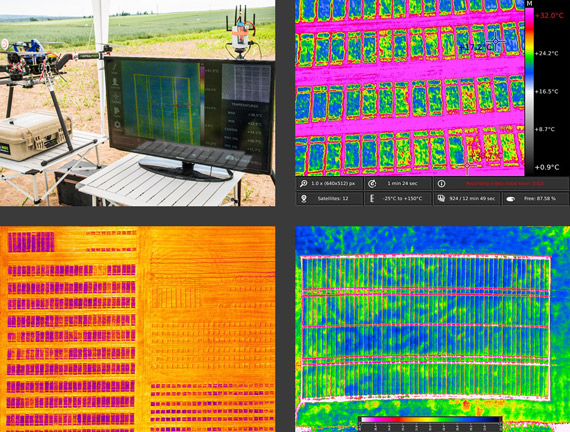

Environmental issues stand at the fore of modern business and politics. Even the mere risk of exhausting non-renewable energy sources has been enough to spur intense research into alternative energy production technologies. Solar energy, an inexhaustible resource, has seen the most use so far, in large part due to government incentives for the construction and support of solar power plants.

Yet operating a solar plant is no simple matter. In addition to precise, high-quality assembly, solar plants require regular maintenance, and each panel must be continuously inspected. A fast, cheap, and reliable method by which operators can inspect an expansive solar array consists in the thermodiagnostic measurements executed by the drone-mounted Workswell WIRIS thermal imaging system.

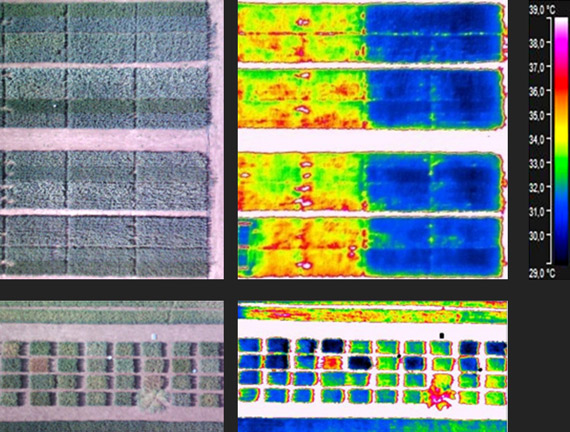

The cultivation of desired properties in a new crop variety is a time-consuming process. Success is dependent on the proper characterization of a large number of potential gene resources.

Given the complexity of this challenge, we decided to put our tools to the test and ran a few experiments in which the genetic resources of minor crops were tested in three-year seed-beds, with an elementary evaluation following the results. The genetic resources evaluated include winter and spring wheat, winter barley, both forms of triticales, vain types of Hordeae, and a number of other minor crops.

The availability of water throughout a crop’s growth cycle is a primary factor affecting the yield, quality, and profitability of agricultural production.

During droughts, plants become stressed and close their stomata, and the vital transpiration process that cools vegetation slows. In areas experiencing climatic variability, monitoring plant temperatures is key to ensuring crop health. Thats also possibility of thermal imaging camera uses.

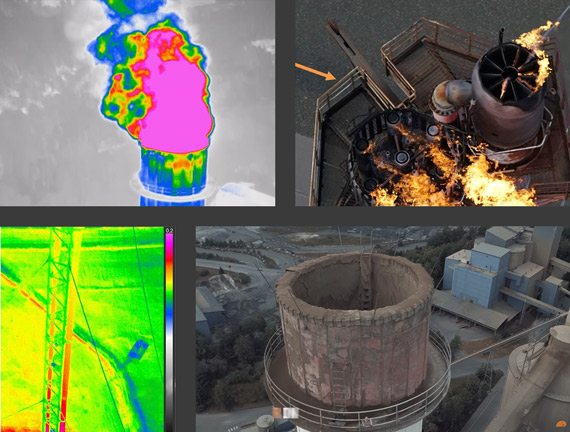

CONDOR Solutions carried out an inspection of the fakel burner at the Lunskoe Onshore Processing Facility, or OPF, in October 2016. The facility is owned by Sakhalin Energy, whose major shareholders are Shell and Gazprom.

Lunskoe OPF sits on the Northeast coast of Sachalin island in Russia. It is located 7km inland, at the influx of the gas-pipeline from the Lunskoe A platform. The entire facility spans over more than 62,000 m².

A thermal imaging camera uses infrared technology to detect heat signatures and create images based on the temperature differences in a scene.

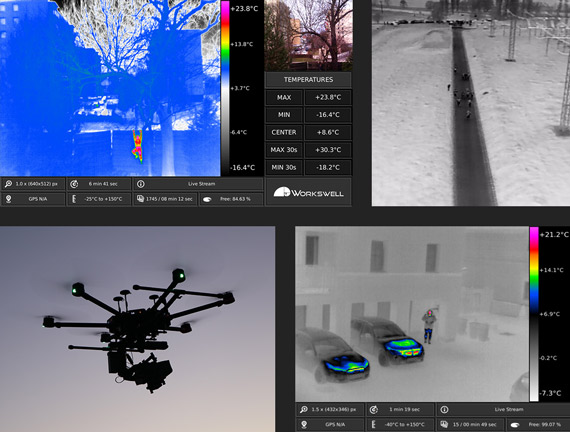

Security is a key concern in all areas of modern life. From cities to companies, churches to communities, safety is simply a priority. Yet despite our best efforts, security is never a settled matter, for new risks constantly arise.

Every organization must work tirelessly to ensure that unauthorized personnel do not enter its premises, while maintaining ease of access for members. Yet identifying an unauthorized person amidst the flow of ingress and egress is very much like searching for missing persons on a foggy evening. Indeed, would-be intruders often utilize the cover of night to penetrate a building’s defenses in search of valuables.

Even the most alert guard can do little when faced with the darkness of a moonless night.

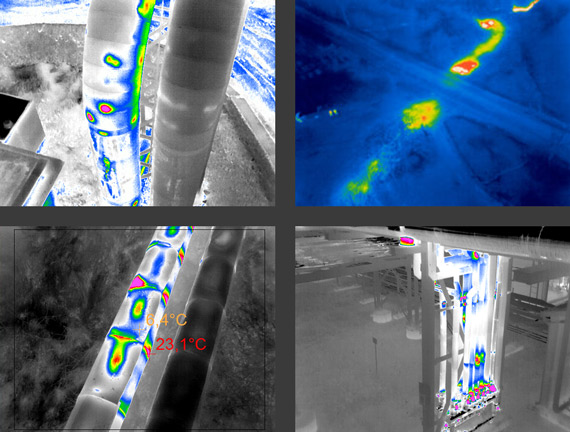

Pipelines are used to transport fluids such as liquids and gases, as well as liquid mixtures with solid particles. Thermographic pipeline inspections are an important component of the effective operation of long-distance piping systems supplying variable media with a temperature different from the temperature of the surrounding atmosphere.

By using thermographic systems, one can quickly detect and localize defects to pipeline insulation, as well as leaks. In some cases, leaks can even be detected and localized in underground pipelines.

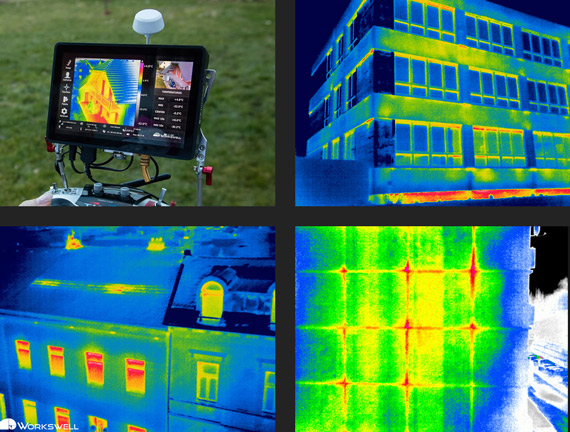

When thermography emerged as a field in the middle of the last century, building diagnostics served as one of its first commercial applications. Even with the limited technologies of the 1960s, thermal cameras could discover a range of construction defects that are invisible to the naked eye.

Today’s thermodiagnostic systems build on those early innovations to provide insight into thermal bridges, water leaks, and faulty insulation before buildings begin to degrade. This is one of most popular thermal imaging camera uses.

Thermal cameras uses have provided indispensable aid to firefighters in recent decades. LWIR thermal cameras do not record visible radiation, but they do ‘see’ long-wave infrared radiation that penetrates through smoke.

With an LWIR thermal camera, firefighters can identify the center of a fire, as well as people lost in smoke or fog. Moreover, a thermal camera paired with a light and easy-to-control drone can be a very useful tool for rescuing missing people.

As you can see, thermal imaging camera uses are various. Thermal cameras also efficiently detect gas leaks that are hazardous for human health and the environment by visualizing them.

The principle behind this method of gas detection is simple: some gases behave as selective radiators with low throughput and reflectivity – and high emissivity. This means that a highly sensitive thermal camera calibrated to the correct spectral range can easily observe a wide range of gases. As a result, special LWIR and MWIR thermal cameras have been developed to detect gas leaks, including, for example, the problematic SF6, which is 24,000x more hazardous for the environment than the greenhouse gas CO2.

So long as the gas is a selective radiator in the spectral range of the thermal camera and its filter, it will be detected.

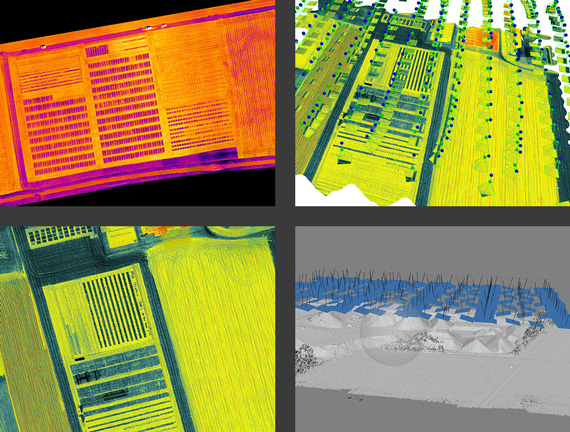

Photogrammetry, 3D mapping and 3D modeling are standard post-processing tools that enhance the presentation and visualization of captured aerial data. With our Workswell WIRIS Pro thermal camera, you can offer your customers and colleagues these enhanced presentations.

The camera’s software allows captured radiometric data to be presented via 3D models and orto-photogrammetics pictures. We also offer a special software for mass thermogram pre-processing (i.e. mass data processing) called Workswell ThermoFormat. This significantly saves time when large numbers of images are pre-processed for mapping and modeling software.

Our data format is compatible with Pix4D and Agisoft, the leading mapping and modeling software programs. We also offer our thermal cameras in bundles with Pix4D and Agisoft.