Fakel Burner Inspection

CONDOR Solutions carried out an inspection of the fakel burner at the Lunskoe Onshore Processing Facility, or OPF, in October 2016.

The facility is owned by Sakhalin Energy, whose major shareholders are Shell and Gazprom.

Lunskoe OPF sits on the Northeast coast of Sachalin island in Russia.

It is located 7km inland, at the influx of the gas-pipeline from the Lunskoe A platform. The entire facility spans over more than 62,000 m².

Introduction

The OPF’s primary function is to process gas and oil from Lunskoe, and to prepare them for transport by pipeline to the export crude oil terminal and the LNG – Prigorodnoe Complex, which produces compressed LNG. It also receives gas and crude oil from the Piltun-Astochskovo-A and Piltun-Astochskovo-B platforms and prepares them for transport to the export terminal in the south of the island. Pumps at the OPF can process up to 195,000 barrels a day. At full capacity, this facility can handle 51 million m³ of gas / day and 9,500 m³ of condensate or crude oil / day. All technological systems at the OPF were commissioned in 2008.

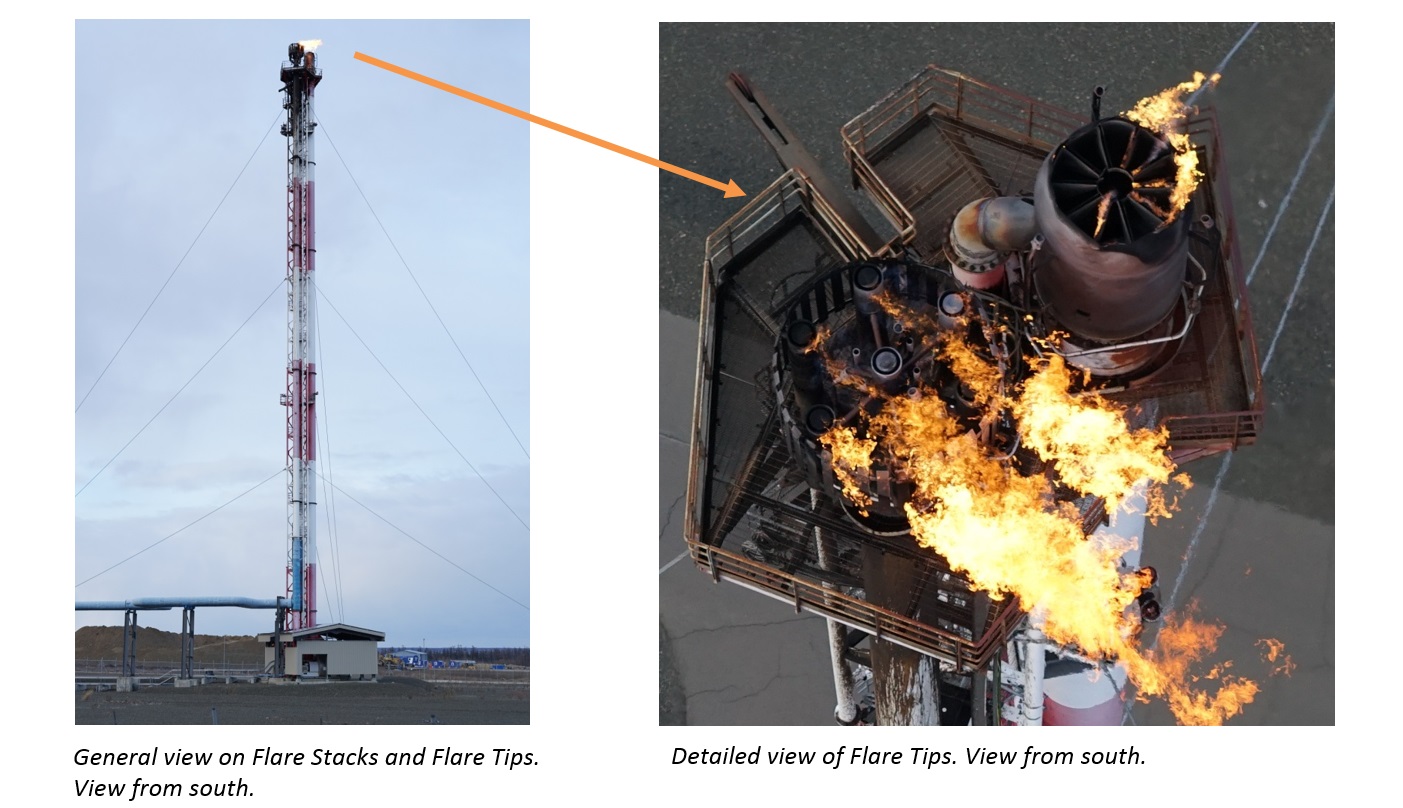

Another important component of the facility is a system of burners, the Flare System, which comprises both low and high pressure units. The Flare System was subject to an inspection carried out by CONDOR Solutions. The weather during the inspection was cloudy, with wind at 14 m/sec and a temperature of -10°C.

Why Inspection Matters

The primary task was to conduct visual inspection aided by UAV technology. However, in addition to the standard camera, a SONY Alpha 7R, we also relied on a thermal camera from Workswell – the Workswell WIRIS thermal camera.

At the OPF, operational technologies are exposed to extreme weather conditions. Burner masts are exposed to very low and freezing temperatures (-) in addition to extreme positive temperatures (+) caused by gas combustion. Therefore, comprehensive thermal imaging inspections of the burner system are a vital part of successful operations.

Take to the Skies

Even an excellent thermal camera has its limits when faced with the expanse of a large roof. A handheld device, even an extraordinarily sensitive one, simply can't cover every corner of a massive complex. Enter the UAV, or drone. In the drone-mounted thermal camera, sensitivity finds its complement in a versatile aircraft. Rather than climb up ladders and skirt unstable surfaces, inspectors can stay on the ground while an airborne patrol makes the rounds up above. Live camera feeds offer an immediate overview of roof condition, and personal inspection is reserved for defects that are recorded by the device.

The Workswell WIRIS

The Workswell WIRIS thermal imaging camera allowed us to measure the temperature of the entire burner system. This thermal imaging camera offers can measure temperatures up to 1,500°C (using a high temperature filter), and it is one of the only high-temperature thermal camera systems available for drones.

Thanks to our measurements, we discovered that the burner system includes both very low temperatures, and very high ones. Therefore, we divided the measurements into two parts. The burner’s mast, from the bottom up to the top service runway, formed the first part. Meanwhile, the second part consisted in the upper part of the burner’s shank.

Conclusion

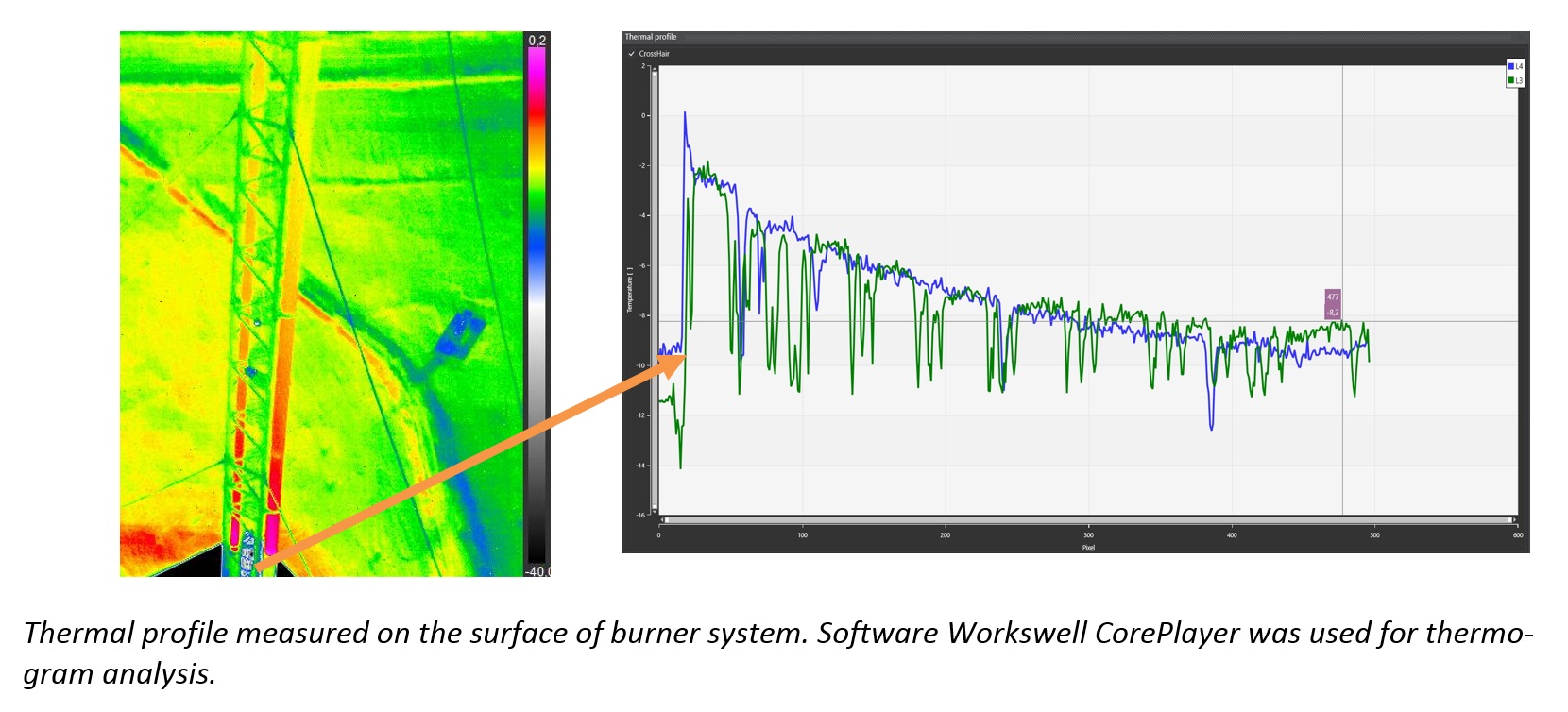

In the first measurement section, we described the temperature of the mast and the rising system of high and low pressure within the pipeline; we also produced a temperature profile, as shown in the figure. The graph and thermogram clearly indicate where the pipeline isolation ends. At this point, the temperature sharply increases. It then gradually decreases with elevation, until we reach the upper part – the shank. At this point, the temperature increases rapidly once again, up to a temperature of about 2,000°C.

Based on the information obtained with the Workswell WIRIS thermal imaging camera and the unmanned aerial vehicle, CONDOR Solutions compiled a final report to provide a detailed description of the condition of the high- and low-pressure burner system. As a result, the operator, Sakhalin Energy, can utilize thermal imaging data to schedule maintenance works so as to minimize interruptions to the production process.