Using thermal cameras to visualize gas leaks

Thermal camera for gas detection can detect gas leaks that are hazardous for human health and the environment by visualizing them. The principle behind this method of gas detection is simple: some gases behave as selective radiators with low throughput and reflectivity – and high emissivity.

This means that a highly sensitive thermal camera calibrated to the correct spectral range can easily observe a wide range of gases. As a result, special LWIR and MWIR thermal cameras have been developed to detect gas leaks, including, for example, the problematic SF< which is 24,000x more hazardous for the environment than the greenhouse gas CO.

So long as the gas is a selective radiator in the spectral range of the thermal camera and its filter, it will be detected.

Thermal camera for gas detection used to detect gases differ from other thermal measuring cameras. In addition to standard components, such as the lens, detector, cooling unit, and image processing electronics, The filter restricts the heating radiation wavelengths that are allowed to act on the detector to narrow the band, which is known as spectral adaptation. In practice, thermal cameras are usually equipped with a special filter to detect one selected gas, or a specified group of gases (i.e., CO)

The detection of other gases is considered as a special “bonus.” Wavelengths of typical band gates for MWIR and LWIR cameras are given in Tab 1. Of course, in practice, we also encounter other types of spectral sensitivity, depending on the expected purpose of the camera.

Camera model | Spectral range of the detector | Typical band gates |

MWIR (medium waves) | 3 – 5 μm (usually InSb) | 3.2 – 3.4μm, 4.52 – 4.67µm 4.2 – 4.4 µm 8.0 – 8.6 µm etc. |

LWIR (long waves) | 9 -11 μm (usually QWIP) | 10.3 – 10.7 μm |

Tab 1: TSpectral response for gas detection cameras

Funkcioning principle

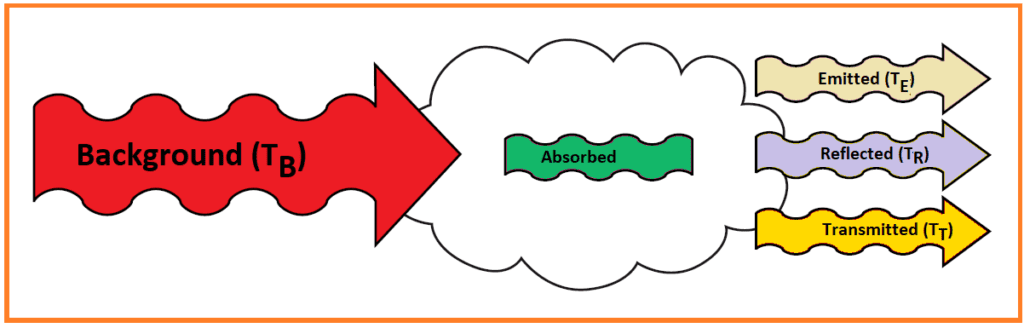

If a thermal camera reads a scene without a gas leak, objects in the angle of view will radiate and reflect infra-red radiation that react through both the lens and the filter on the detector.

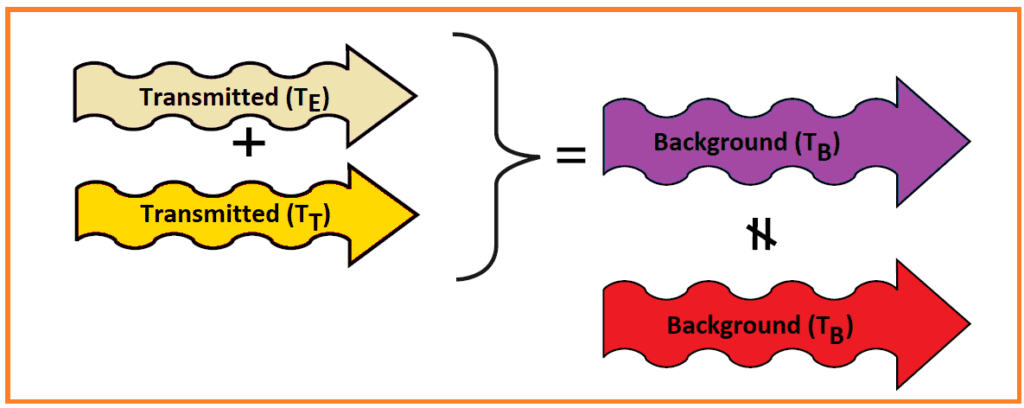

The filter only lets some wavelengths of radiation enter the detector, from which the camera generates an uncompensated image of the radiation intensity of the radiation – this corresponds to the apparent temperature. If there is a cloud of gas between the lens and the thermal camera, the gas will selectively absorb radiation to the extent of its spectral absorption and the amount of radiation passing through the gas which affects the detector will be lower. See Fig. 1. and Fig. 2 for a schematic.

To see the gas against the background, there must be a high contrast between the cloud and the background. In other words, the amount of radiation leaving the cloud must not be the same as the amount of radiation entering it. In fact, the amount of radiation reflecting off the molecules in the gas cloud is very small and can be ignored. The key for a gas’ visibility is the difference between its temperature and the background temperature.

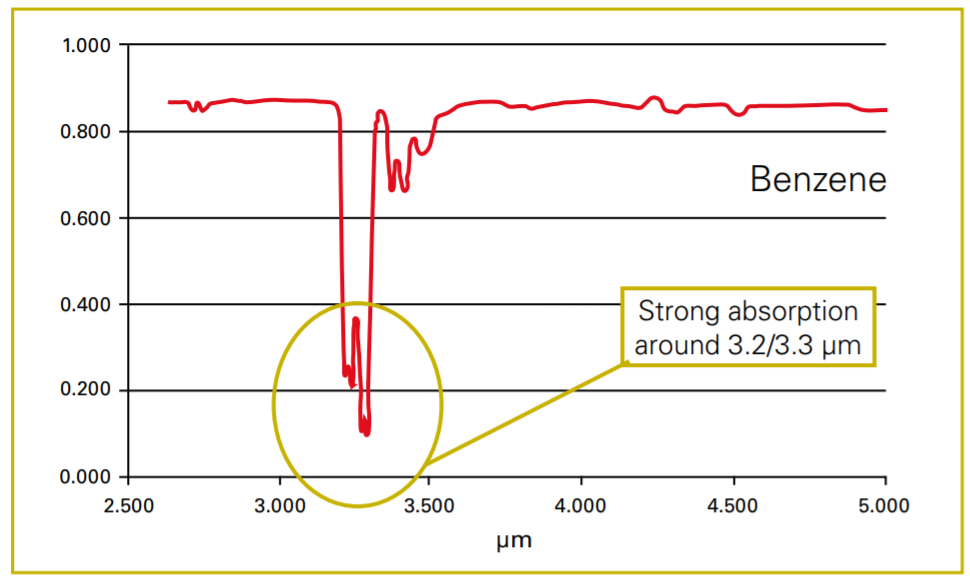

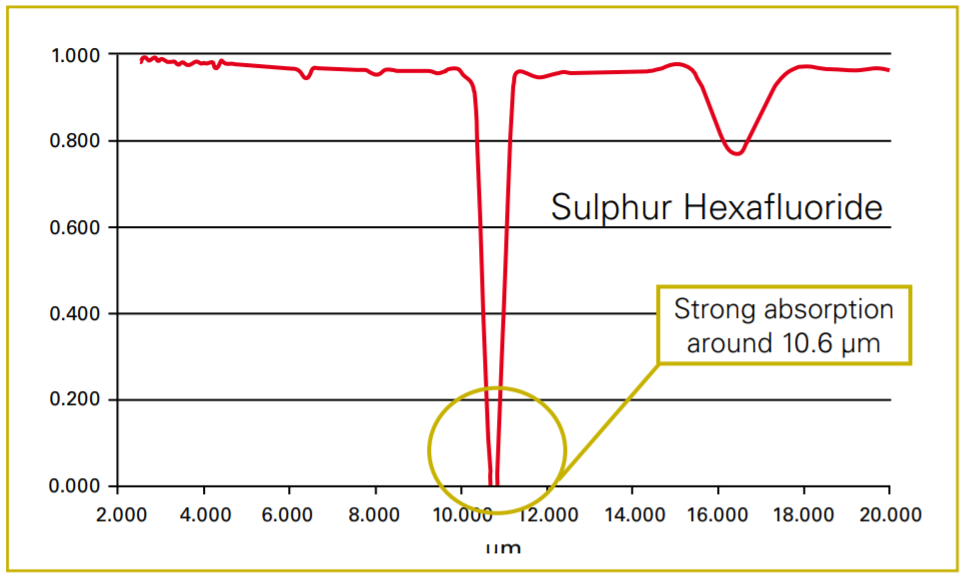

As a result, it is very important to know the spectral absorption of individual gases – their absorption spectrum. To determine the absorption spectrum of infra-red radiation for a gas, a sample is placed in an infra-red spectrometer and the absorption, or transmission, of infra-red radiation is measured at various wavelengths. The result is then graphed as the spectral absorption line, e.g. in Fig. 3 or Fig. 4.

The American National Institute of Standards and Technology (NIST) is one of the verified sources of the spectral characteristic data of individual gases. NIST’s web database is a very useful source of this information.

The key conditions for gas visibility on a thermal camera readout are as follows:

- The gas must absorb infra-red radiation in a wavelength that is visible to the thermal camera and optical filter

- The gas cloud must have a high bright contrast compared with the background

- The instantaneous gas temperature must be different than the background

- The gas cloud’s movement helps its visibility

Those interested in a detailed physical explanation of the principles are referred to our publication.

Gas Leak Detection with MWIR Thermal Cameras

The Workswell GIS-320 IR camera is an MWIR thermal camera designated for unmanned aircraft (drones). [1] This thermal camera for gas detection has a cooled InSb detector, a resolution of 320×240 px, and a spectral range of 3.2 – 3.4 μm. Due to its dimensions (201x150x105 mm) and weight (1. 6 kg), it cannot be classified as a small device. However, a DJI M600 Pro drone can keep the GIS320 in the air for 20 minutes. The camera is displayed in this configuration in Fig. 5. When mounted on a drone, the GIS320 IR camera can monitor hazardous gas leaks, in addition to a range of technologies that are difficult to access.

The following gases can be detected with this method: Benzene, Ethanol, Ethylbenzene, Heptane, Hexane, Isoprene, Methanol, MEK, MIBK, Octane, Pentane, 1-Pentane, Toluene, Xylene, Butane, Ethane, Methane, Propane, Ethylene and others.

Conclusion

Gas emissions contribute to the growth of global warming. Industrial firms pay billions of dollars for emissions in regulation penalties and damage, and the leaks represent a fatal risk for both employees and local residents.

Thermal camera for gas detection inspections can detect the leaks of dozens of volatile organic compounds, including the greenhouse gas sulphur hexafluoride. Detecting gases with a thermal camera enables leaks to be caught for tens of volatile organic compounds, including greenhouse gas sulphur hexafluoride.

A specialized thermal camera for gas detection is a fast, contact-less measurement tool which can be used in difficult-to-access places. It can detect small leaks from several meters away, as well as larger leaks at hundreds of meters of distance. It can also detect leaks on moving vehicles, which significantly increases the safety of both the inspector and the inspected item.

To ensure success, inspectors must select a suitable spectral range (MWIR or LWIR) and utilize a band pass filter depending on which gases are to be detected.